By Don Beckwith, Senior Vice President – Finance and Administration

Today, every organization struggles to find the most effective way to channel internal communications among its employees. Across many departments, how do we best synchronize our conversations as we design, build, deliver and service our products? Deadlines challenge us to balance our digital exchanges with old-fashioned human interaction.

Dictionary.com defines information fatigue syndrome as “a weariness or overwhelming feeling of being faced with an indigestible or incomprehensible amount of information.” That’s what we face in today’s age of data overload, both at work and at home. So we ask ourselves… are high-tech tools compounding the problem? A study reported in Inc. noted that half of the average employee’s time is spent on email and other “necessary, yet unproductive tasks.”

New York Times columnist Sherry Turkle observed that we’re sacrificing meaningful conversation for expedient connection. Increasingly, we are hiding behind email, IM messages and various social media channels rather than having a real-time conversation.

LifeHack and OnlineITDegree.net recently published a useful (and funny) Do I Really Need to Send That Email? decision tree-infographic to help us re-think how we manage our In and Out boxes.

Here are a few helpful tips:

-

Do you sit near the colleague(s) receiving your emails? Walk over and talk to them or set up a brief meeting.

-

Think twice about the people that you’re cc’ing. For every 100 people needlessly cc’d, 8 work hours are lost. (TechCrunch)

-

Avoid forwarding a thread of multiple emails to a new recipient who will need to read the entire anthology in order to understand what you need; a true time-waster!

-

A big no-no: Using email to negotiate a contract or resolve an issue.

-

Is what you’re trying to communicate more than a couple paragraphs? Does it require a series of detailed decisions or responses? Schedule a face-to-face or phone meeting.

-

Is the decision maker or team located in another state or country? This is where technology rules. A number of solutions—including videoconferencing, Skype, GoToMeeting and FaceTime—help us easily collaborate without the need to travel to other locations to be productive.

-

Is the news extremely important? Confidential? Bad? Shut off the computer and get in front of the person who needs to hear it.

Admittedly, today’s digital communication tools play an important role in our daily business interactions. However, we need to make an extra effort to engage in face-to-face conversations and fight the urge to shoot off an email or text!

By Bob Sobolewski - President and CEO at ebm-papst Inc.

By Bob Sobolewski - President and CEO at ebm-papst Inc.

Insight #1: Up your game to meet changing requirements.

Insight #1: Up your game to meet changing requirements.

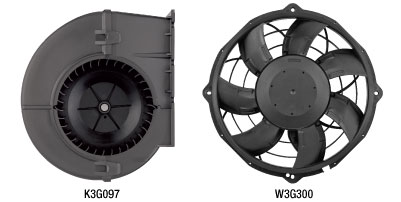

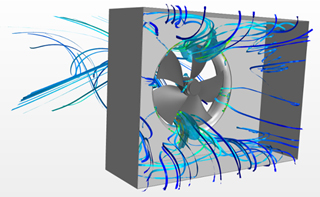

configurations for air movement in high-performance electronic devices and the infrastructure that supports them and highlighted its

configurations for air movement in high-performance electronic devices and the infrastructure that supports them and highlighted its

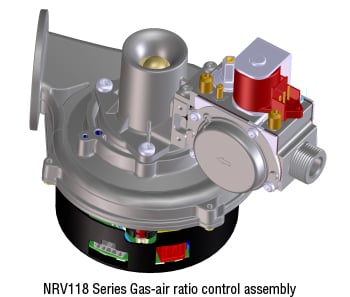

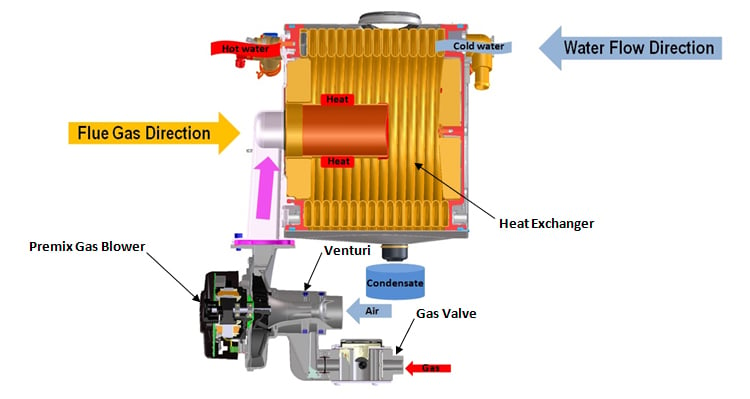

by Dave Hillburn, Business Development Manager - Heating

by Dave Hillburn, Business Development Manager - Heating Heat Exchanger: Commonly made up of either stainless steel or aluminum, this is where heat is transferred from the combustion process into the water, and then moved through the hydronic system.

Heat Exchanger: Commonly made up of either stainless steel or aluminum, this is where heat is transferred from the combustion process into the water, and then moved through the hydronic system.