by Dave Hillburn, Business Development Manager - Heating

Whether they’re used for home heating, supplying a university building with hot water, or warming the turf on a football field, condensing gas boilers are the most efficient way to heat water in a hydronic heating system. Although common and used daily, most people are uncertain about the basic principles and components of these systems. With that in mind, the following is a review of how high efficiency condensing gas boilers work: the basics of combustion, the meaning of high efficiency in terms of boiler operation, and types of components in a condensing gas boiler.

Combustion basics

Combustion is an exothermic reaction (meaning it gives off heat) that occurs when you rapidly mix air and fuel in the proper ratio. Air mixed with hydrocarbons such as natural gas, oil, and propane, produces in heat, carbon dioxide, and water vapor. These are commonly referred to as products of combustion, and make up the flue gases that exit the boiler via the flue or chimney.

What is a high efficiency condensing gas boiler?

Boilers have been used in hydronic heating systems for hundreds of years to create and move hot water through pipes and deliver heat. These systems differ from furnaces in that they move water instead air through them. Until about 25 years ago, home heating boilers were mid-efficiency (80-85%) products with flue gas temperatures typically around 350°F. In a high efficiency boiler, the flue gases are usually around 135°F and efficiencies of 95% or greater can be achieved. This difference in flue temperature is where high efficiency boilers get part of their extra efficiency; extracting more heat from combustion out of the flue gases and putting it into the hydronic system. In fact, these products are so efficient and pull so much heat out of the flue gases that the water vapor in these gases actually cools and condenses, changing state from vapor to liquid. Hence, the name condensing gas boiler.

The other facet contributing to the high efficiency of condensing gas boilers is the combustion air fan can fully modulate its speed as compared to a single stage, full on or off, device found on typical mid-efficiency boilers. This modulation means the blower can adjust its speed to the varying input rates needed during the fall and spring months. Therefore, the boiler input rate can better match the demand of the heating system. Consider your conventional mid-efficiency boiler as a car with only two speeds: full on or off. In contrast, a high efficiency condensing gas boiler, with a fully modulating ebm-papst blower, is capable of running at full on, off, or any speed in between. The result is a more efficient boiler and meets the demand of the system, even when the full heat input isn’t needed.

Components of a high efficiency condensing gas boiler

Now that we understand the combustion process and the basic concepts of a high efficiency condensing gas boiler, let’s take a look at the components that make up the boiler system.

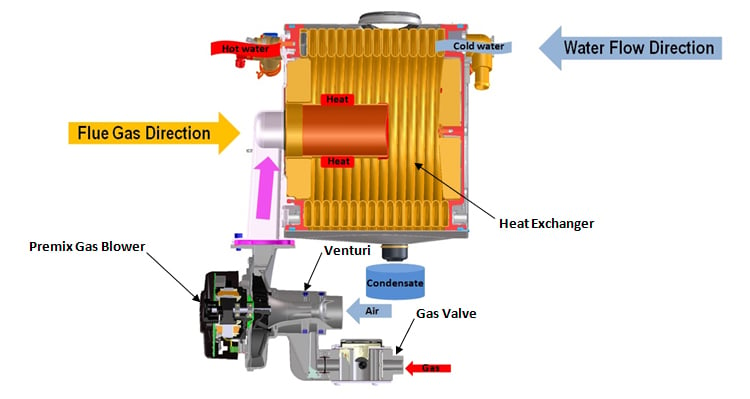

Heat Exchanger: Commonly made up of either stainless steel or aluminum, this is where heat is transferred from the combustion process into the water, and then moved through the hydronic system.

Heat Exchanger: Commonly made up of either stainless steel or aluminum, this is where heat is transferred from the combustion process into the water, and then moved through the hydronic system.

Premix Gas Blower: Delivers premixed air and fuel to the burner where combustion takes place.

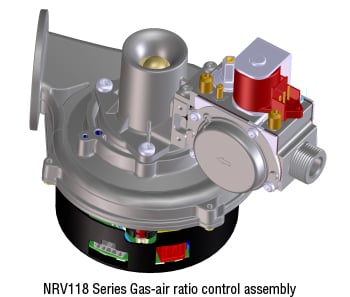

Venturi Mixer: A channel through which combustion air travels and induces negative pressure on the gas valve, allowing gas to flow and mix with the air in the blower.

Gas Valve: Responds to the pressure signal from the venturi and controls the flow of gaseous fuels into the system. It also acts as a safety shutoff; closing off the flow of fuel if the boiler is not running.

Condensate Collection System (Not Shown): This system safely collects the condensate formed in the heat exchanger and removes it from the system.

Boiler Control (Not Shown): An electronic module that monitors the safety limits and general operation of a condensing gas boiler.

These systems work together in balance to control the combustion process and heat input into the hydronic system. At the heart of the system, the premix gas blower, constantly modulating and adjusting to meet the demand of the application. The next time you’re looking to upgrade or replace your existing boiler you now have an understanding of the basic principles behind these devices and can make the engineer’s choice, a boiler with ebm-papst on the inside.

About Dave Hillburn

Dave Hillburn works with ebm-papst customers to incorporate the right system solutions into their residential and commercial heating applications. With seven years hands-on experience in combustion design, he helps optimize these systems’ output and energy efficiency. A graduate of Central Connecticut State University with a BS in Mechanical Engineering Technology, Dave enjoys playing drums and guitar, sports and travel.