The fifteenth "Product of the Year" was presented on March 14, 2013, and ebm-papst achieved first place with the high-performance DV6300 diagonal compact fan.

Readers of Elektronik and elektroniknet.de chose the DV6300 as the 2013 Product of the Year in the category "Electrical Engineering" from among 111 nominated products. The award recognises the most innovative and ground-breaking products in the industry. Peter Metzger, Manager of Business Development and Marketing for ebm-papst St. Georgen GmbH & Co. KG, accepted the distinction at the awards ceremony in Munich: "We are gratified to receive this recognition from the readers of Elektronik. The DV6300 demonstrates how we are setting new standards in state-of-the-art development and production methods."

Readers of Elektronik and elektroniknet.de chose the DV6300 as the 2013 Product of the Year in the category "Electrical Engineering" from among 111 nominated products. The award recognises the most innovative and ground-breaking products in the industry. Peter Metzger, Manager of Business Development and Marketing for ebm-papst St. Georgen GmbH & Co. KG, accepted the distinction at the awards ceremony in Munich: "We are gratified to receive this recognition from the readers of Elektronik. The DV6300 demonstrates how we are setting new standards in state-of-the-art development and production methods."

The winning product from ebm-papst has an electronically controlled S-Force motor with additional options such as temperature regulation, active motor cooling and filter monitoring with signal output for filter change. The diagonal compact fan is ideal for applications with strict requirements regarding air performance with high backpressure, limited installation space and a low operating noise level.

To lower noise in these applications, there are standard "fixes" that the designer can call upon to help meet the required noise and performance levels. With axial fans, the common fix is to reduce the motor RPM and increase the number of fans to handle the air performance needs and or increase the blade size. These solutions can lead to a reduction in system performance, add components increase the system footprint and increase energy consumption. Not an appealing solution with today's high electrical costs, small installation areas and increased refrigeration costs. Even worse, in many cases, these changes are not always effective and further fixes must be done on site where additional changes are even more costly.

To lower noise in these applications, there are standard "fixes" that the designer can call upon to help meet the required noise and performance levels. With axial fans, the common fix is to reduce the motor RPM and increase the number of fans to handle the air performance needs and or increase the blade size. These solutions can lead to a reduction in system performance, add components increase the system footprint and increase energy consumption. Not an appealing solution with today's high electrical costs, small installation areas and increased refrigeration costs. Even worse, in many cases, these changes are not always effective and further fixes must be done on site where additional changes are even more costly.  ebm-papst Inc. has recently replaced all the heating and cooling units in the main production areas at the U.S. headquarters in Farmington, CT. The units that were removed were mostly installed in 1998. Originally, we had only one gas fired central heating system in the assembly area (circa 1985) and one more gas fired central heating system in the sheet metal area (circa 1994). We added 9 separate air conditioning units in 1998.

ebm-papst Inc. has recently replaced all the heating and cooling units in the main production areas at the U.S. headquarters in Farmington, CT. The units that were removed were mostly installed in 1998. Originally, we had only one gas fired central heating system in the assembly area (circa 1985) and one more gas fired central heating system in the sheet metal area (circa 1994). We added 9 separate air conditioning units in 1998.

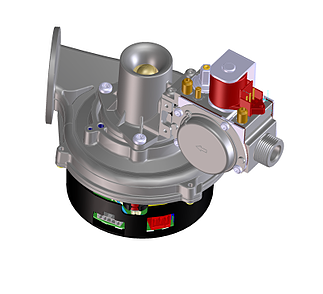

Vroljik and his crew aren’t done yet: They’re putting the final touches on NRV Series products for appliances rated up to 500 MBTU/H (150 kW). These will be launched in January at the

Vroljik and his crew aren’t done yet: They’re putting the final touches on NRV Series products for appliances rated up to 500 MBTU/H (150 kW). These will be launched in January at the

Why are we not utilizing our natural resources more effectively? What I saw during a recent trip to ebm-papst’s global headquarters in Mulfingen, Germany offers a vision for what the United States could achieve.

Why are we not utilizing our natural resources more effectively? What I saw during a recent trip to ebm-papst’s global headquarters in Mulfingen, Germany offers a vision for what the United States could achieve.