by Tom Costello, Market Manager - Appliance & Heating

Commercial food equipment engineers are always on the look out for opportunities to improve the cooking performance of their gas fired appliances; therefore, recent industry design trends are taking a page from the comfort heating industry’s, condensing boiler technology. For more than 20 years the comfort heating industry has been perfecting the gas-air ratio control (GARC) system to modulate the combustion energy to the heat demand of the home, optimizing efficiency and reducing energy consumption. Now these same GARC assemblies are being applied to today’s gas fired commercial cooking applications for combi-ovens, conveyor ovens, and fryers.

Combi-ovens offer chefs the opportunity to utilize in one appliance three cooking modes while precisely maintaining the cooking temperature for (a) convective cooking, (b) steam cooking, and a (c) combination steam and convective cooking. This multi-operational design is applied to counter-top to floor standing combi appliances that satisfy the demands of a small restaurant to a large institutional kitchen. The GARC technology allows for all three of these modes to existing in a fast acting but controlled release of energy that more efficiently cooks the food products.

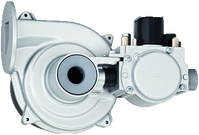

Gas fired fryers also utilize the modulating GARC technology to respond to changes in load demand while offering precise temperature control of the oil for cooking and warm-up profiles. The GARC assembly is made of three main components: a premix ready gas blower, air-fuel mixer (venturi), and zero governor gas valve. The combination of all three of these components allows for the precise control of gas and air to be delivered to the burner in a constant ratio that also allow for variable gas-air input by speed controlling the blower.

Premix ready gas blower, venturi, and zero governor gas valve

This gas-air ratio control provides a pneumatic coupling between the blower and the gas valve via the venturi allow for the gas and air to be modulated by sending a variable speed signal to the blower motor. The result of this modulating combustion technology applied to cooking appliances is the precise temperature control, rapid response to load changes, and energy conservation during off peak hours that benefit either the restaurant owner, chef, or customer.

To learn more about this technology, please don’t hesitate to contact ebm-papst sales or marketing.